Pavement Investigation & Design

Pavement Investigations

This is a critical first step in the pavement design process. Our team will put together a proposal that follows VicRoads and Austroads recommendations and that takes local conditions into account.

Our in-house traffic controllers are qualified to provide traffic management plans and services on all municipal and private roads, saving on third-party costs.

Test Pit Excavation

We excavate test pits using hand tools, offering several advantages to using heavier machinery. We are able to log the pavement and soil layers more accurately, collect soil samples with a higher degree of precision, and leave less of an impact on the existing pavement. For rigid pavements, we use a concrete corer and reinstate with quickset, making the area safe and usable.

FWD & LWD Testing

We can organise Falling Weight Deflectometer testing and use the results to design asphalt overlays and other partial reconstruction options. For smaller areas, we can undertake Light Weight Deflectometer testing and achieve comparable data to FWD testing.

Laboratory Testing

We use several NATA-accredited laboratories around Victoria for geotechnical and geoenvironmental testing. In addition to the standard pavement design tests, we can conduct Unconfined Compressive Strength tests, dust suppression testing, and abrasion tests for unsealed roads.

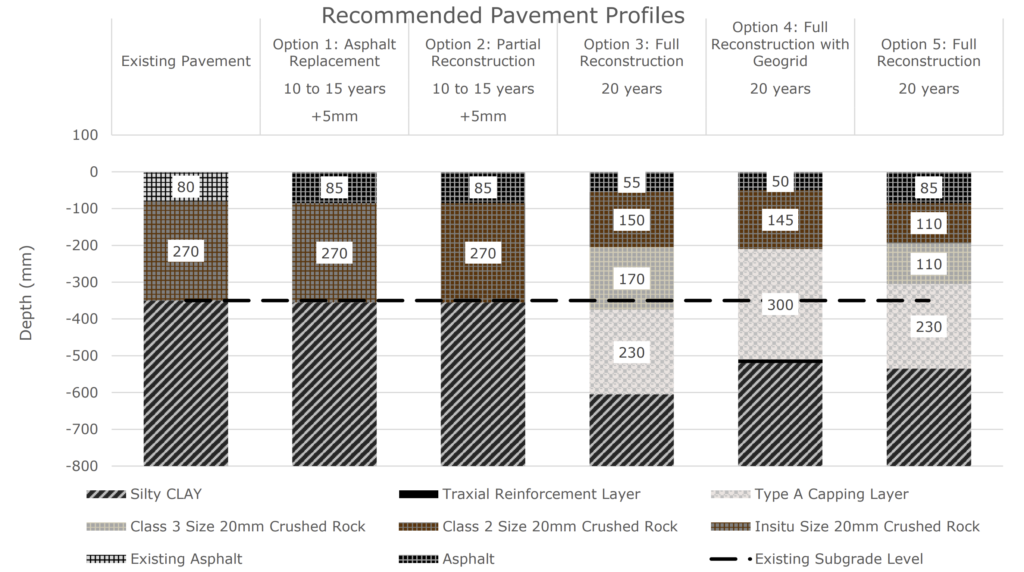

Pavement Designs

We employ a systematic approach to pavement design that primarily relies on Austroads design guides, but also software such as CIRCLY 7.0 which is used to confirm our design assumptions. During the reporting and design phase, we work closely with our clients to determine design levels, drainage options and construcability issues. We typically provide multiple options for each pavement, including partial- and full-reconstruction designs. We can also provide options for recycling the existing pavement materials through the stabilisation of pavements and subgrades. Foam bitumen stabilisation is another option that may be suggested.